Mulching head teeth is a critical component of mulching attachments used on skid steers, excavators, and other heavy machinery for land clearing, forestry, and agricultural packages. These teeth are designed to shred and pulverize plant life, brush, and small timber into satisfactory mulch. Comprised of high-power, put-on-resistant substances which include carbide, metallic, or tungsten, mulching head teeth offer sturdiness and durability in harsh operating conditions.

The teeth are arranged in diverse styles at the rotor to ensure green slicing and even distribution of the mulch. Ordinary maintenance and timely replacement of worn teeth are vital to preserving the performance and efficiency of the mulching head. Properly selected and maintained mulching head teeth improve productiveness, lessen equipment downtime, and make contributions to extra effective land management practices.

Mulcher Teeth Head Innovative In Tooth Technology

Modern tooth technology has converted mulching operations, offering superior performance, prolonged lifespan, and advanced performance. This text delves into the key improvements that are revolutionizing mulcher teeth head generation.

Advanced Materials

One of the primary improvements in mulcher teeth head technology is using superior materials. Traditional mulcher teeth had been generally made from well-known metal, which, even as long-lasting, frequently fell brief in terms of longevity and resistance to wear. Modern mulcher teeth now incorporate excessive-power alloy steels, carbide, and other composite materials. Carbide-tipped teeth, in particular, have emerged as famous because of their advanced hardness and put-on resistance.

Optimized Tooth Design

The layout of mulcher teeth has additionally visible giant improvements. Modern-day mulcher teeth are engineered with optimized shapes and reducing angles to maximize performance and minimize resistance. Using laptop-aided layout (CAD) and simulation equipment has allowed producers to create teeth that reduce correctly and require much less power. These optimized designs contribute to quicker mulching speeds and lower gas intake, making mulching operations more low-cost and environmentally pleasant.

Self-Sharpening Technology

Every other revolutionary feature in modern-day mulcher teeth is the self-sharpening era. Traditional mulcher teeth tend to dull quickly, necessitating common polishing or substitutes. Self-polishing teeth are designed to hold a pointy edge at some point in their lifespan. This generation involves the strategic placement of different materials in the teeth, ensuring that as the teeth wear down, they keep showing a pointy aspect. This innovation substantially reduces protection time and expenses, allowing operators to cognizance greater on the venture handy rather than system preservation.

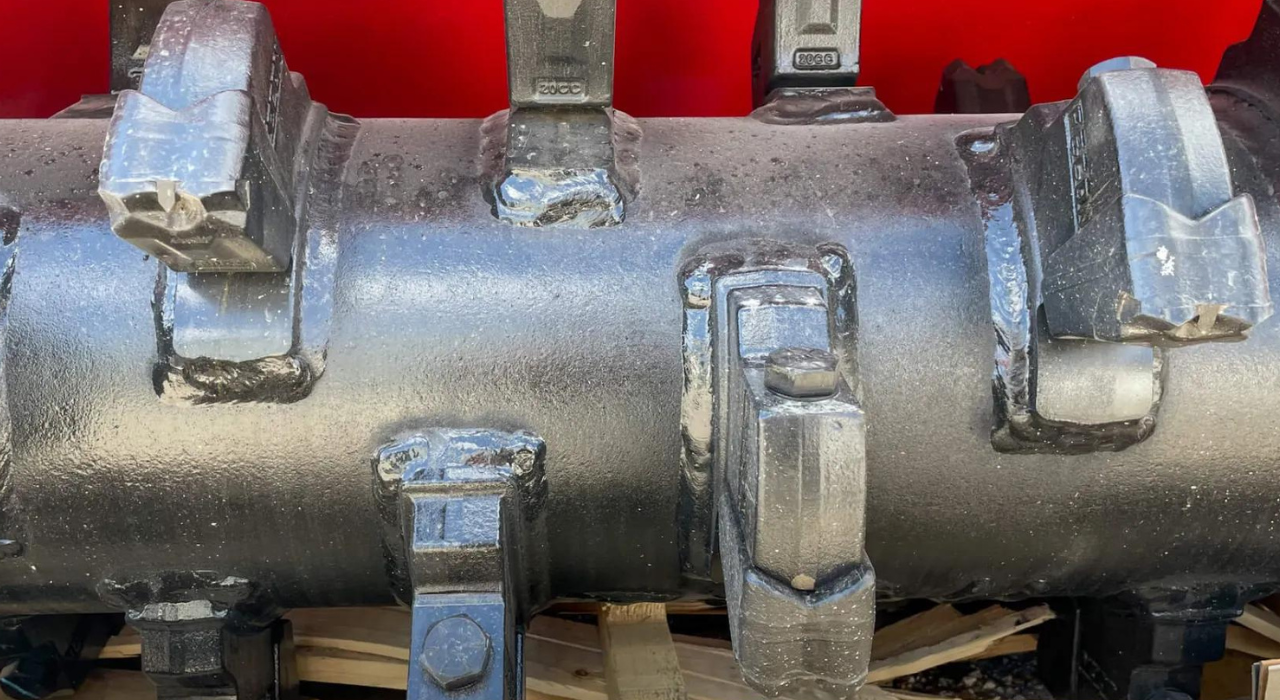

Improved Mounting Systems

The mounting systems for mulcher teeth have additionally advanced, offering more flexibility and ease of substitution. Brief-change structures and bolt-on designs have replaced traditional welded teeth, making it less difficult to update worn or broken teeth on websites. These systems now not handiest reduce downtime but also allow operators to personalize their mulcher heads with one-of-a-kind teeth types and configurations based on precise activity requirements. This adaptability enhances the flexibility of the mulching gadget and improves ordinary operational performance.

Enhanced Durability and Impact Resistance

Modern production processes and material remedies have led to mulcher teeth which might be extra durable and proof against impact. Heat treatment, hardening, and coating technology have all contributed to the improvement of teeth that can withstand the harsh conditions of mulching. teeth handled with strategies inclusive of induction hardening or coated with put-on-resistant substances like tungsten carbide can endure heavy use and withstand chipping or breaking. This extended durability translates to longer provider life and decreased replacement costs.

Environmental Consideration

Cutting-edge improvements in mulcher teeth generation also consider environmental concerns. Advanced teeth designs and substances no longer best enhance overall performance but also lessen the environmental effect of mulching operations. For example, more efficient slicing of teeth reduces gasoline consumption and emissions, contributing to a decreased carbon footprint. Additionally, using longer-lasting substances and a self-sprucing era reduces the frequency of tooth replacements, minimizing waste and selling sustainable practices.

Final Words

Modern teeth generation in mulcher tooth heads has delivered about massive advancements in performance, durability, and environmental sustainability. Through the usage of superior substances, optimized designs, self-polishing generation, progressed mounting structures, improved sturdiness, and the mixing of facts and analytics, modern-day mulcher teeth are transforming the way mulching operations are performed. These innovations now not simplest gain operators via reducing fees and downtime but also contribute to extra sustainable and environmentally pleasant land control practices.